Here are the most frequently asked Interview questions on PLC. This article aims to cover most of the interview questions on programmable logic controllers so as to prepare you to crack a job interview.

List of Interview questions on PLC

- What is a PLC?

- How does a PLC control a process?

- Draw the basic architecture of a PLC system

- What are the basic components of a PLC system?

- What are the types of programming languages used in PLC?

- What is the role of CPU in PLC?

- What is the role of rack or chassis in PLC?

- What is meant by ladder logic?

- Functional Block Diagram

- What is meant by scan cycle?

- What is meant by scan time?

- What is an HMI?

- What are the different types of inputs and outputs in a PLC?

- Why is 4-20mA analog signal preferred over 0-20mA?

- What is the difference between 2-wire and 4-wire?

- What is the difference between source mode and sink mode?

- What are the different types of redundancies in PLC?

- What are the commonly used communication protocols in PLC?

- What is a register?

- What is the difference between alarms and events?

What is a PLC?

PLC stands for ‘Programmable Logic Controller’. It is an industrial computer used to control a process in an industry according to the instructions (program) downloaded to its memory.

How does a PLC control a process?

A PLC controls a process by collecting data from the field using input modules, process them according to the downloaded programs and decide a course of action, and command something to control a physical device.

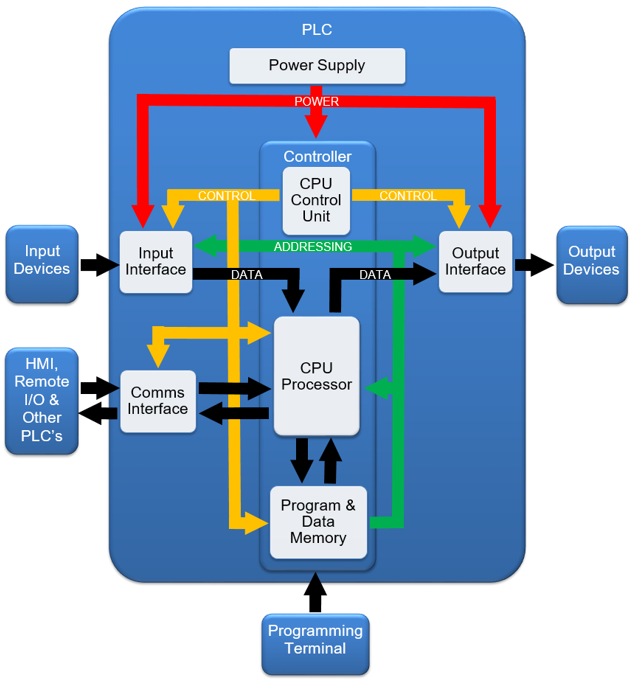

Draw the basic architecture of a PLC system

What are the basic components of a PLC system?

A programmable logic controller consists of the following components:

- Power Supply

- CPU

- Input Modules (DI/AI/PTC cards)

- Output Modules (DO/AO/PTC cards)

- Communication Module (Profibus/ModBus etc.)

What are the types of programming languages used in PLC?

- Ladded Logic

- Function Block diagram

- Sequential Function Chart

- Structured Text

- Instruction List

What is the role of CPU in PLC?

The CPU acts as the brain of the PLC. The program created by the developer is downloaded into the CPU. The CPU continuously runs this program, detects the input states, and generates the output.

What is the role of rack or chassis in PLC?

The chassis accommodates the power supply, CPU, IO devices, communication, and interfacing modules. In addition to that, it distributes power to all those devices and acts as a communication link between those modules.

What is meant by ladder logic?

Ladder logic is a commonly used programming language in PLC. This program is equivalent to switching circuits. It has two vertical lines called power rails and circuits are made between these two lines, as horizontal lines are called rungs. Each rung represents an operation in the control process. When the PLC is in the run mode, it executes each rung left to right, from the top to bottom and once it reaches the end, it promptly resumes at the start and the cycle continues as long as the PLC is in the run mode.

Functional Block Diagram

Functional block diagrams are graphical representations of functionality or certain operation in PLC. Functional blocks have predefined functionality, where it processes the inputs and generates the output. An example of a functional block diagram performing the same task that the above ladder logic does is shown below:

What is meant by scan cycle?

The PLC executes the program by a repetitive process known as the scan cycle. During each scan cycle, the PLC reads the status of inputs from the IO modules, executes the program from the top to the bottom, and writes the outputs. This process is known as the scan cycle in PLC. It can be better understood from the below diagram.

What is meant by scan time?

Scan time is the time consumed by the PLC to read the input cards, execute the program and generate output. The scan time of a plc depends on the size of the program, the number of I/Os, and the amount of communication required.

What is an HMI?

HMI stands for Human Machine Interface. It is a graphic user interface that is used to give commands to the PLC and monitor the field devices. In brief, it is used to interact with PLCs.

What are the different types of inputs and outputs in a PLC?

Basically, PLC inputs and outputs are classified as follows:

(Click on the above links to learn more about each one of them)

Why is 4-20mA analog signal preferred over 0-20mA?

The key reasons behind the usage of 4-20mA instead of 0-20mA are:

- 4mA is considered as engineering zero. That makes 0.0mA is an invalid input. Hence, 0mA to the analog input means that the circuit is open and there is no current flow in the circuit.

- 4-20mA makes it easy to find wire breaks.

- In a 4-20mA two wired system, the field instruments get their power in the same line as the signal.

What is the difference between 2-wire and 4-wire?

In a 2-wire transmitter, a pair of twisted cables are used and the power for the transmitter and its output is transferred through this twisted pair.

Whereas, in a 4-wired transmitter, one pair is used to power the transmitter and the other pair is used to transmit the signal.

What is the difference between source mode and sink mode?

Source mode and sink mode refers to the direction of current flow in a digital input. In source mode, the DI port itself acts as a voltage source whereas in sink mode the DI port acts as a ground.

What are the different types of redundancies in PLC?

- CPU redundancy

- Power supply redundancy

- IO module redundancy

- Communication module redundancy.

What are the commonly used communication protocols in PLC?

- ModBUS RTU

- ModBUS TCP/IP

- Profibus / Profinet

- CANbus

- EtherNet/IP

- HART

- DeviceNET

- DNP3

- InterBUS

- MelsecNet

What is a register?

A register is a memory location in PLC in which data can be stored. This data can be analog or digital depending on the type of register.

What is the difference between alarms and events?

An alarm is a warning of abnormal process conditions whereas any operations or change in state is an event.

The above questions are the most frequently asked interview questions on PLC.